- PCB Blog

- Future Trends of Flexible Circuit Boards

- Rigid-Flex PCB Stack-up for Impedance Controlled Designs

- Control Impedance Between Rigid PCB and Flex PCB

- Flex PCB Reliability and Bendability

- Normal Flex PCB Specifications

- Flex PCB Polyimide Coverlay and Solder Mask

- Flex PCB Boards and Connectors

- About RA Copper and ED Copper

- Introduction of Flexible PCB

- 5 Tips For Designing Flexible PCB

- Advantages of FPC (Flexible PCB)

- Evolution of the Flex Printed Circuit Board

- Benefits of Using Flex Circuit Boards

- Why Rigid-Flex PCBs are Economical?

- Flexible PCB vs Rigid PCB

- Development of Flexible printed circuit board (FPC) market

- Traditional Manufacture Engineering of FPC Substrate

- Development Trend of FPC Board

- Flex PCB and the Manufacturing

- About Flex PCB design

- About Flex PCB and Assembly

- How to Ensure Flex PCB Design Success

- How to Select the Appropriate FPC Materials?

- The Differences In Rigid PCB, Flex PCB and Rigid-Flex PCB

- Flex-Rigid PCB Design Guidelines

- Beneficials for Polyimide Flex PCB Boards

- About Stiffener on Flex PCB FPC circuit Boards

- About ENIG and ENEPIG

- PCB Surface Finish Comparison

- Copper Thickness for FPC Boards

- Interconnect Solutions for Flexible Printed Circuits and Etched Foil Heaters

- Advantages and Disadvantages of Rigid-Flex PCB

- About FPC Plating Process

- About EMI shield design for Flex Printed Circuit Board

- PCB Assembly Blog

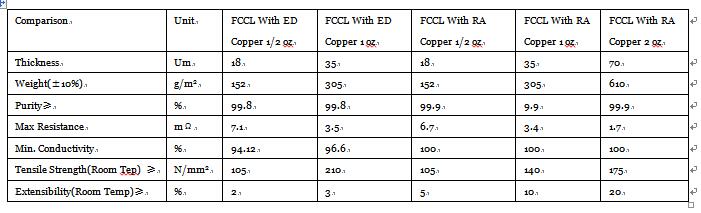

The base material for FPC is FCCL and the structures are Copper +PI, Copper + AD + PI, Copper + PI +Copper or Copper + AD + PI + AD + Copper.

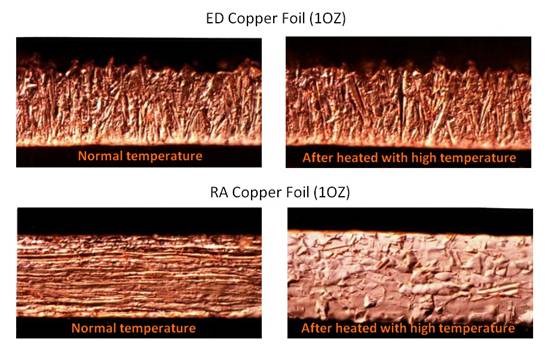

Originally, copper is very key for the flex circuits material. Which kind of copper we could choose? The answer is ED Copper (Electrodeposited Copper Foil) and RA copper (Rolled Annealed Copper Foil). Then what the difference between these two? I will show it from below 4 aspects:

1. Definition & Manufacturing Method

Different copper is defined by its manufacturing method. ED Copper, which is made from CuSO4 solution, by using electrolysis method, made Cu2+ dip into spinning cathode rolls and stripping, then made it into ED copper. RA Copper, which is made from high purity copper(>99.98%), by using pressure process, made copper into different copper thickness.

2. Form

ED Copper (Electrodeposited Copper Foil) and RA Cooper (Rolled Annealed Copper Foil)

3. Performance

Due to different manufacturing methods and different shapes, the performance of them is not same. ED copper has better conductivity than RA copper. While as for extensibility, RA copper is much better than ED copper.

4. Application

Because of different performances, RA copper and ED copper are used in different products which tend to different product requests. Normally, ED copper is always used for static application and RA copper is always used in dynamic application. For example, the flex board needs to be bendable a lot, so obviously, RA copper will be a good choice. Otherwise, we could use ED copper with high electrical conductivity. Whatever, you should select copper according to your circuits' requests (final board performance, cost, function...)