Phone:086 18018732119

24 hours quick lead-time*

Affordable price for PCB prototype and Assembly

On-Time Shipping by Fedex or DHL, etc.

Great Quality Approved By Valued Customers

10 Years Professional Team Supported

24/7 assistance service

No MOQ & No Limit

ISO/IATF/UL/RoHS Compliant

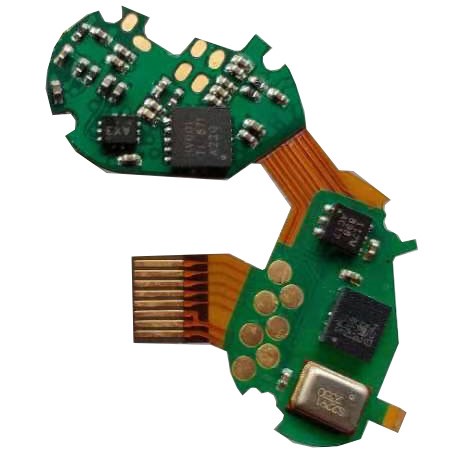

Flex PCB & Assembly

Rigid-Flex PCB & Assembly

Rigid PCB & Assembly

Quick PCB Prototype | SemiPCBLearn More

PCB Production | SemiPCBLearn More

Turnkey PCB Assembly including PCB Manufacturing, PCB Assembly and Components Sourcing Services. You will get the final PCBA boards as your design files requried.Learn More

Standard PCB and PCB assembly service for FR4 PCB, HDI PCB, Aluminum PCB, Copper PCB, Rogers PCB, etc. Learn More

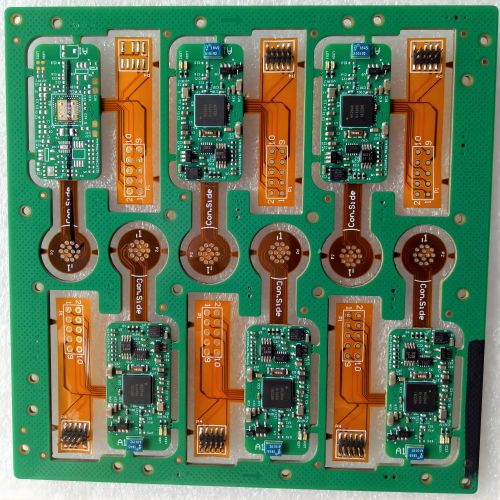

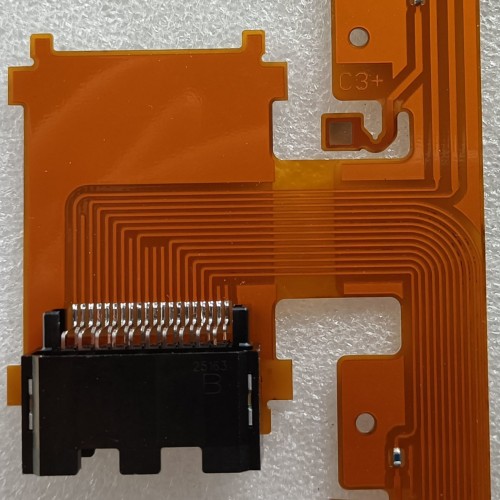

2Layer_Rigid-Flex PCB and Assembly

This PCB (Printed Circuit Board) is a 2Layer Rigid-Flex PCB made with FR4 + PI material and mounted with components on top side

Read More

2Layer_Rigid-Flex PCB and Assembly

This PCB (Printed Circuit Board) is a 2Layer Rigid-Flex PCB made with FR4 + PI material and mounted with components on top side

Read More

4Layer_Rigid-Flex PCB and Assembly

The Printed Circuit Board is 4Layer Rigid-Flex PCB made with FR4 + PI material and mounted with some SMD components and THT parts

Read More

4Layer_Rigid-Flex PCB and Assembly

The Printed Circuit Board is 4Layer Rigid-Flex PCB made with FR4 + PI material and mounted with some SMD components and THT parts

Read More

6Layer_Rigid-Flex PCB and Assembly

Rigid-Flex PCB and PCB Assembly with both sides

Read More

6Layer_Rigid-Flex PCB and Assembly

Rigid-Flex PCB and PCB Assembly with both sides

Read More

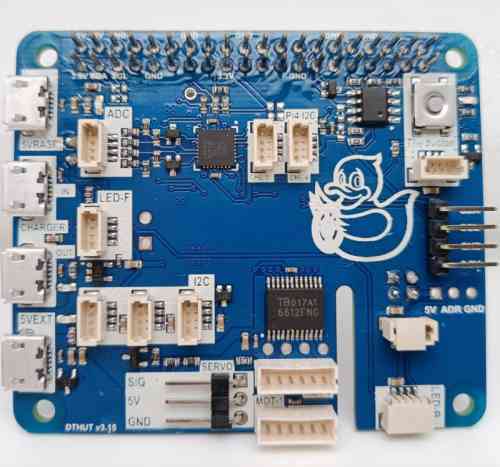

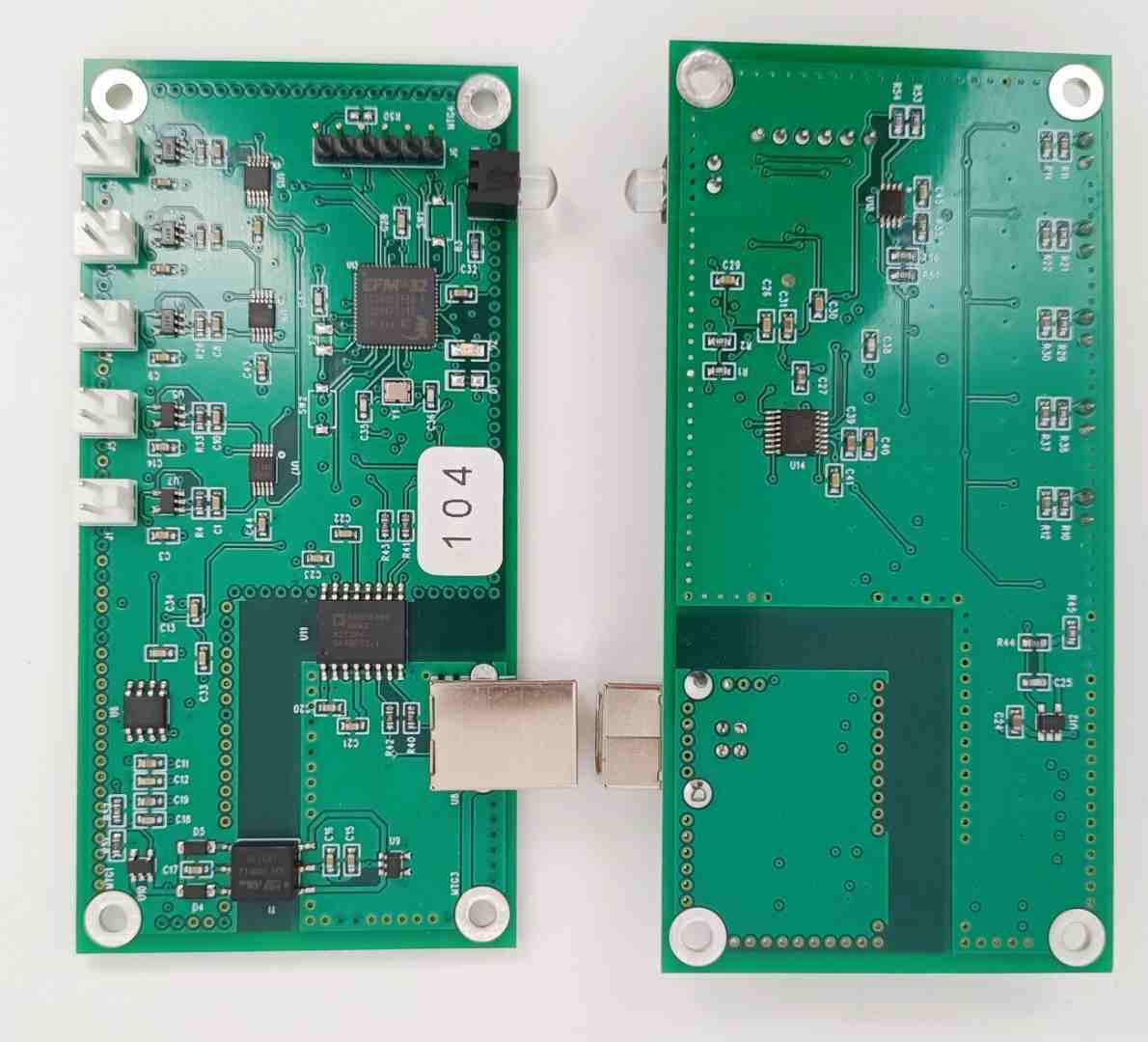

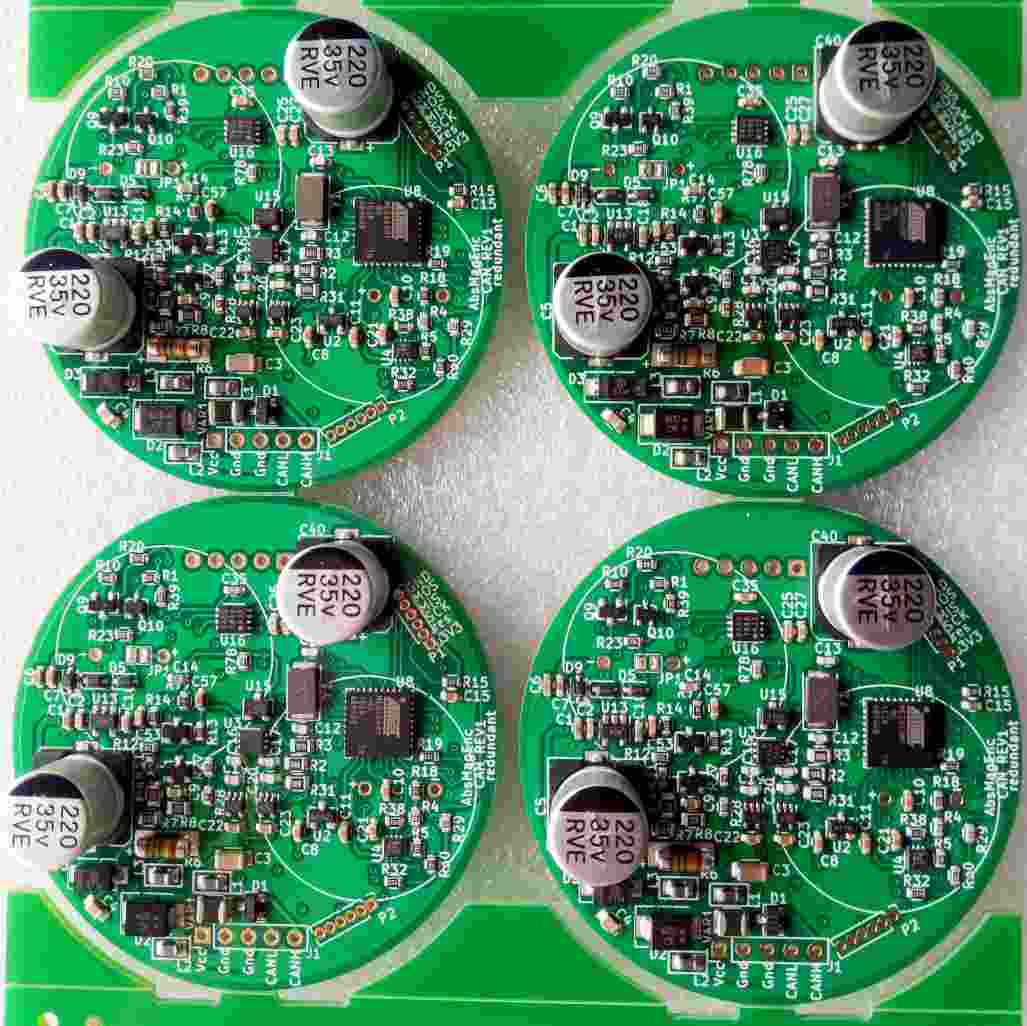

FR4_2Layer PCB and Assembly

2Layer FR4 PCB SMT Assembly & THT Assembly on One Side

Read More

FR4_2Layer PCB and Assembly

2Layer FR4 PCB SMT Assembly & THT Assembly on One Side

Read More

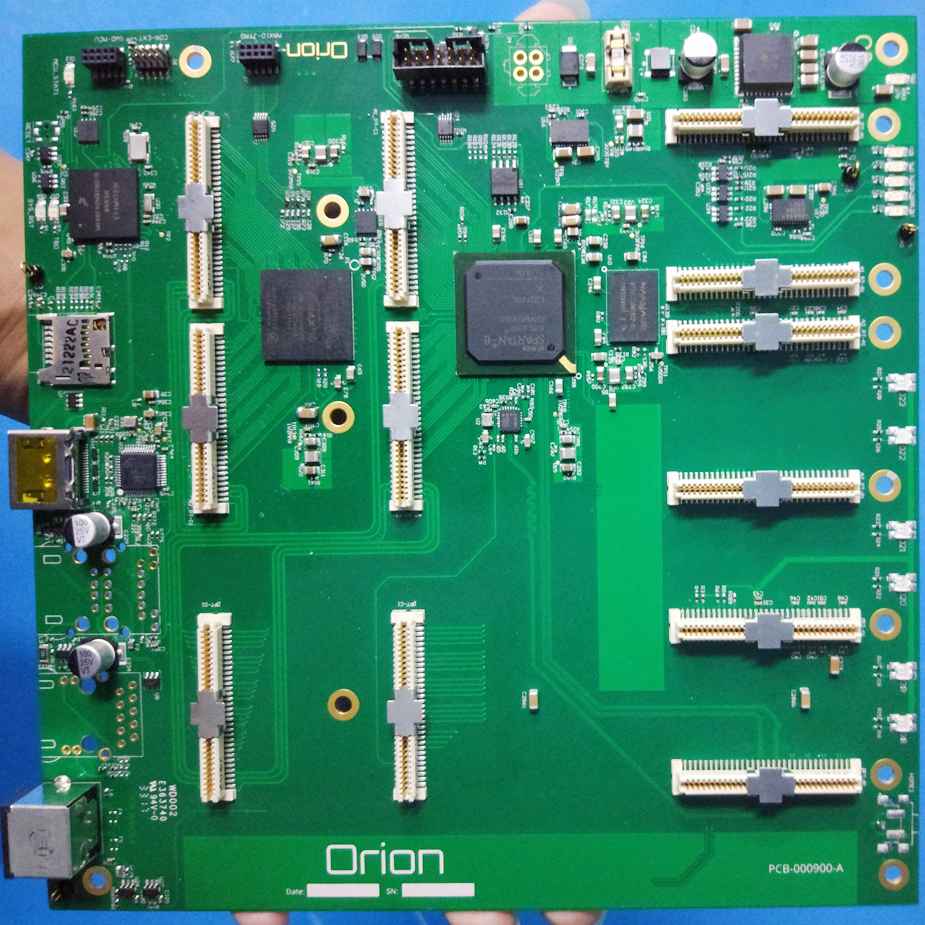

FR4_4Layer PCB and Assembly

4L PCB and PCB Assembly on both sides with SMT assembly and THT assembly

Read More

FR4_4Layer PCB and Assembly

4L PCB and PCB Assembly on both sides with SMT assembly and THT assembly

Read More

FR4_6Layer PCB and Assembly

6Layer Rigid FR4 PCB and PCB Assembly with SMT assembly and THT assembly

Read More

FR4_6Layer PCB and Assembly

6Layer Rigid FR4 PCB and PCB Assembly with SMT assembly and THT assembly

Read More

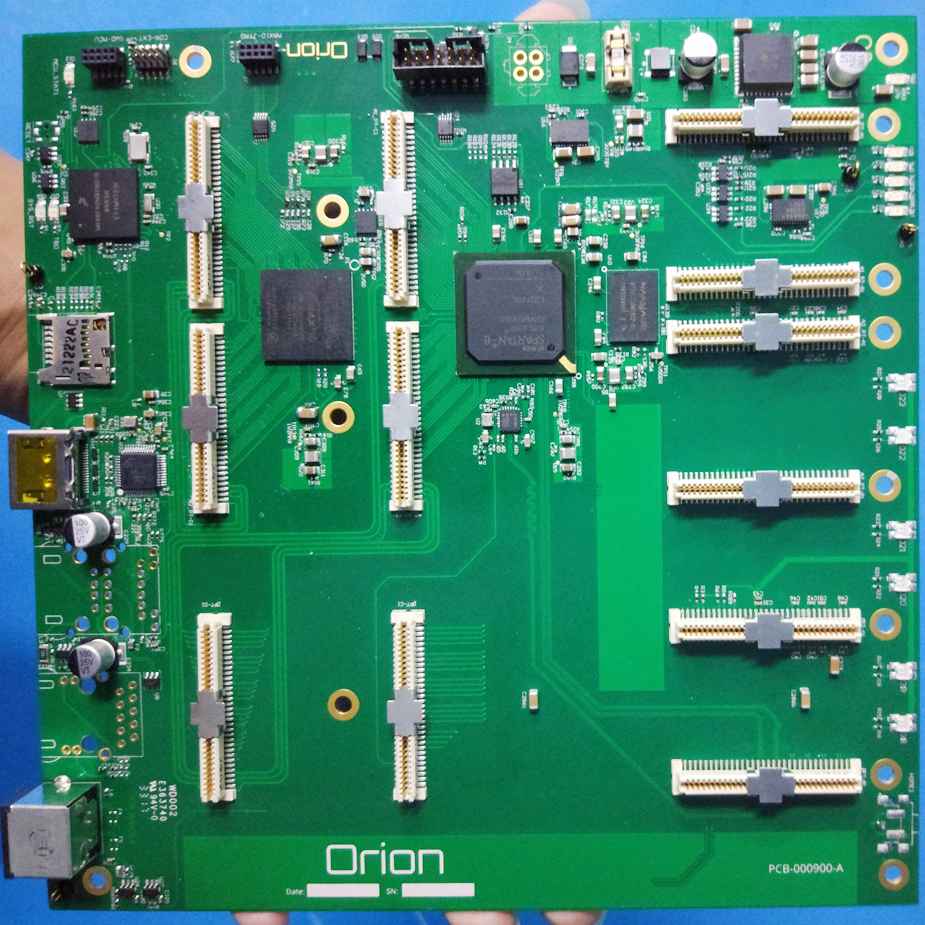

6Layer HDI Rigid-flex PCB and Assembly

HDI Rigid-Flex PCB and PCB Assembly with both sides

Read More

6Layer HDI Rigid-flex PCB and Assembly

HDI Rigid-Flex PCB and PCB Assembly with both sides

Read More

8Layer HDI PCB and Assembly

8Layer Rigid FR4 PCB and PCB Assembly with SMT assembly and THT assembly

Read More

8Layer HDI PCB and Assembly

8Layer Rigid FR4 PCB and PCB Assembly with SMT assembly and THT assembly

Read More

12Layer HDI PCB and Assembly

HDI 12Layer PCB and PCB assembly for SMT assembly & THT Assembly

Read More

12Layer HDI PCB and Assembly

HDI 12Layer PCB and PCB assembly for SMT assembly & THT Assembly

Read More

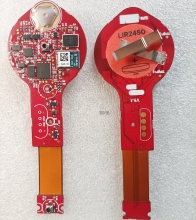

1L Flex PCB Assembly

1L Flex PCB and PCB Assembly with SMT Assembly

Read More

1L Flex PCB Assembly

1L Flex PCB and PCB Assembly with SMT Assembly

Read More

PCBA, short for printed circuit board assembly, refers to the combination of PCB, components and electronic accessories. Simply speaking, PCBA is actually the blank PCB boards assembled with SMD components and THT components. This article provides a comprehensive introduction of PCBA from which everybody will learn much.

MoreIn the early stage, all PCBs were assembled with components by hand using only a solder iron. With the development of technology, components size on PCB boards getting smaller and smaller, and the components quantity getting more and more. It become more difficult to assemble by hand and impossible task for big production order. Thus auto SMT assembly and auto THT assembly was developed as well.

MoreResponsible Printed Circuit Board (PCB) manufacturers all inspect boards on different positions in the process of assembly in order to eliminate appearance defects and find out numerous assembly errors prior to electric testing and collect data for statistical process. The inspection of PCBA boards always include: Visual inspection, AOI, X-Ray, FCT Test, ICT Test, etc. The crucial step for this goal lies in the implementation of rigorous quality administration system. Progress and wider application of SMT (Surface Mount Technology) brings about higher requirement for inspection because solder joints applying SMT have to withstand more stress than those applying via plating technology.

More

4,000 More

served customersin 30 countries

5000 More

different part numbersdelivered annually

99.5%+

customer satisfaction rate